Paper, cardboard and printing

The fine art of paper production and processing has resulted in a wealth of high-quality paper grades that are perfectly matched to their respective applications. Each of these grades has its own manufacturing process since cutting requires more knowledge than material width and thickness. Karl Rudolf Dienes faced this challenge: He took the problems of the then still few paper manufacturers and converters as his homework and developed knives and systems that solved precisely these problems.

DIENES know-how

The numerous patents held by DIENES mills and their worldwide use do not result solely from the ambition to produce the highest quality cutting systems. They are also the result of intensive research, as in this case on the behavior of different paper grades during the cutting process, and the outcome of many customer discussions and joint problem solving. This has certainly also contributed to the fact that DIENES slitting systems are international leaders in precision, reliability, long operating times and short set-up times.

DIENES offers its customers in the paper manufacturing and processing industry numerous applications that are optimally adapted to the various paper types and textures. Our paper knives convince with high quality material, which ensures maximum service life as well as an optimal cutting edge with reduced dust generation.

DIENES profitability analyses at major international paper manufacturers showed an increase in knife service life by a factor of 10 to 30 when switching to specially adapted DIENES cutting systems. If you add up the longer machine running time, the lower maintenance effort and the material savings due to less false running, the investment in state-of-the-art slitting technology also has a quick and significant effect on the operating result.

Ask us for our reference list of international paper manufacturers who have been using DIENES slitting systems successfully and reliably for years.

The printing and packaging industry

Especially when converting paper for the printing and packaging industry, the highest demands are placed on low dust, cut edge quality and, last but not least, the service life of the cutting tools used. The cutting process used for this purpose is shear cut, whereby the following indispensable requirements must be met: On the one hand, optimum adjustment and adherence to the setting parameters such as shear angle, knife overlap, plunge depth and a reproducible axial contact force of the upper knives against the respective lower knife edge. On the other hand, the exact design of the cutting tools to the respective material to be cut and the production machines. Then it comes down to the knife material, surface quality and chamfer design, and last but not least the resharpening quality, which must be adapted to the respective conditions.

In the printing industry, knife systems are used both in the printing presses and in the downstream finishing machines. Due to the difficult ambient conditions, particularly high demands are placed here on the reliability and ease of maintenance of the tools. Depending on the various finishing machines, a wide range of cutting tools are used, for example paper cutting knives, folding knives, paper drills, circular knives, perforating knives, punshing knives, triple cutting knives, scraper knife, trimmer knives, paper knives and cutting sticks. In the case of circular knives, there are systems with upper and lower knife shafts and corresponding knife collars, as well as systems with knife holders in various cutting widths and speed ranges. On the lower knife side, expansion shafts, slitting bushs and individually driven knives are used. In addition, straight knives (cross cutters) are also used here for formatting.

Cutting single-ply paper

We have also worked extensively on cutting single-ply papers. We know the criteria and the measures to be taken at the factory to achieve the best possible cutting results even at over 3000 m/min.

With single-ply paper, the condition for an exact, clean and low-dust cut is a paper web that is uniformly tensioned by web tension and fed to the cutting station at high speeds without wrinkles or waves. Shear cutting is particularly well suited for this purpose. In addition to the use of shafts and bushings, pneumatic or electrically driven shear cut knife holders as well as motor-driven bottom knives can be used. Such technologies are preferred nowadays due to the shorter set-up times and, on the other hand, to achieve top speeds of over 3000 m/min and higher safety standards.

Cutting multilayer paper

We are also familiar with the special features of cutting multi-ply paper. For multi-ply paper, in sheeters and cut size machines, the DIENES tip-to-tip method is the key to success. Since the maximum knife load is limited between 600 – 800 g/m² basis weight depending on the paper grade, DIENES has modified the classic shear cut to have both top and bottom knives driven by electric motors.

Sanding and abrasive belts

We have also developed optimal cutting technologies in crush cutting and shear cutting for cutting emery and abrasive belts. Typical problems in crush cut are also dust accumulation, tool life, unclean cutting edges and too low cutting pressures.

DIENES solutions are based on the optimization of the dished and top knives by adapted cutting geometry, hardness and material selection. Shear cut and crush cut knife holders must be completely sealed so that the functionality is not impaired. In shear cut, backlash-free vertical and horizontal guidance of the cutter heads of type PSGs DF and PSG DF is crucial.

For crush cut, it is advisable to increase the cutting pressure of the crush cut holders such as PQDS or PQAS by means of multi-cylinders. A backlash-free vertical guidance of the cutter heads for crush cut holders is made possible by the cutter shater type PQA DF.

Matching DIENES products

-

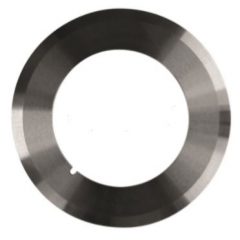

![The picture shows three different cutting rings from DIENES.]() Circular knives

Circular knivesCutting rings

Diameter 77-250 mmShow more -

![Circular knives - dished knives]() Circular knives

Circular knivesDished knives

Diameter 62-200 mmShow more -

![The goal of a DIENES knife is to achieve more performance, maximum tool life, minimum setup times and high cutting edge quality with minimum changeover effort.]() Circular knives

Circular knivesFlat top knives

Diameter 90-220 mmShow more -

![The picture shows DIENES grooved knives and multiple grooved knife blocks.]() Circular knives

Circular knivesGrooved knives

Diameter 46-250 mmShow more -

![DIENES multiple grooved knife blocks for an optimal cutting result.]() Circular knives

Circular knivesMultiple grooved knife blocks

Diameter 77-490 mmShow more -

![A DIENES bottom knife.]() Circular knives

Circular knivesBottom knives

Diameter 105-300 mmShow more

-

![DIENES Straight knives for cutting.]() Straight knives

Straight knivesStraight knives for granulators and recycling

Show more -

![Pictured is a DIENES straight knife range.]() Straight knives

Straight knivesCross cut knives and roll splitting knife

Show more -

![The picture shows cutting sticks from DIENES.]() Straight knives

Straight knivesCutting sticks

Show more -

![Straight knives - Foil knife and serrated knife]() Straight knives

Straight knivesFoil knives and serrated knives

Show more -

![Pictured is a range of paper cutting knives, tack cutter, three-knife trimmer and trimmer knife.]() Straight knives

Straight knivesPaper cutting knives, tack cutter, three-knife trimmer and trimmer knife

Show more