Mayr-Melnhof Baiersbronn Frischfaser Karton GmbH

The company

The company Baiersbronn Frischfaser Karton GmbH belongs to the Mayr-Melnhof Group and produces virgin fibre based cartonboard.

The challenge

Virgin fibre based cartonboard consists of different types of board, the top and back are made of pulp and the middle is made of groundwood. A perfect cut cannot be easily achieved with this cardboard using a conventional slitting system.

The solution

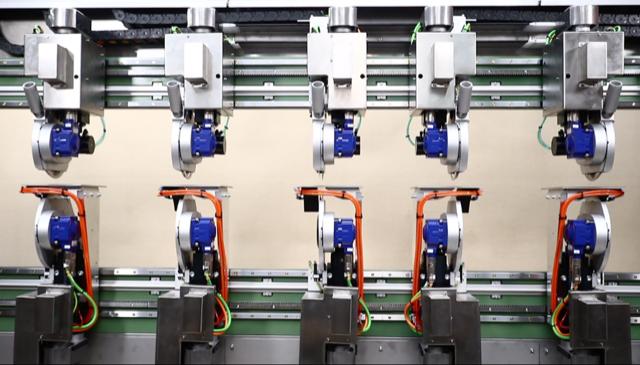

Jagenberg equipped this line with a mechanical twin cut technology. With this technology, a top knife with a very sharp grinding is used instead of the classic bottom knife. In conventional systems, on the other hand, the bottom knife is a carbide cup knife. With twin cut, the respective pair of circular knives penetrates the paper webs from both the top and the bottom layers. Thanks to a DIENES invention, the cutting point is shifted to the centre of the material to be cut, regardless of the number of layers. This is the only way to ensure constant cutting quality for all layers for grammage up to 1,000 g/m² with an unprecedented overall quality.

The implementation

At the Baiersbronn plant, all existing cutting units had to be mechanically and electrically overhauled. At the cost summary, it quickly became clear that the repair costs would turn out to be very high, and at the same time technology remains outdated. This is where DIENES came into play; the equipment manager remembered well that DIENES is the inventor of the twin cut technology and the best on the market. After about 3 years of project work and intensive trials in the DIENES cutting laboratory, the investment was approved. Based on constructive discussions and corresponding dimensional measurements by DIENES engineers, the system was designed for the sheeter. Event though only 4 days remained for the assembly itself, namely the turn of the year, the installation and commissioning were successfully completed within the scheduled period. This was only possible thanks to the detailed project planning and the very good cooperation with the equipment manager and technicians from Baiersbronn.

We have increased knife life from 5 weeks to 11 weeks and reduced format changeover from 2 minutes to 5 seconds.Markus Gaiser, Equipment Manager at Mayr-Melnhof Baiersbronn Frischfaser Karton GmbH

The solution – DIENES 4.0

The Jagenberg sheeter 4 Synchro Board 528 built in 2000 with a working width of 2800 mm and a speed of 350 m/min has been modernized with a DIENES SIMU-FLASH cutting system with twin cut technology. In addition to the technical upgrade, the cross cutter is also up to date in terms of the DIENES smart support service. The experts in Overath can access the system remotely at any time and thus solve malfunctions quickly and specifically. The planned update with TEOC, the in-house data tracking system, means that machine failures and malfunctions are no longer left to chance. All accruing machine, environmental and service data are recorded, processed and evaluated as required. Continuous data recording of the cutting parameters and automated condition monitoring detect the actual condition of the knives. This in turn can then be used, for example, to identify conclusions and indicators of abrasion at an early stage and use these findings accordingly to improve the cutting process. In detail, TEOC smart solutions enable the customer to achieve lower production costs, higher product quality, predictive maintenance and increased cutting knowledge.

The outlook

After one year of operation, equipment manager Markus Gaiser has clearly drawn his conclusion “our new DIENES cutting unit has moved us from the Stone Age into the high-tech world. The plant runs trouble- free. Dust generation has been drastically reduced. We’ve increased knife life from 5 weeks to 11 weeks and we reduced format changeover from 2 minutes to 5 seconds.” Such investments pay for themselves in a very short time, and we ensure high safety standards for our operating personnel.

| Customer details | |

|---|---|

| Category | Company details |

| Foundation | 1950 |

| Paper mills | 7 |

| Sales | 2.52 billion euros |

| Employees | 10.000 |