Straight knives & guide rails

Decades of experience have made DIENES knives the epitome of quality and precision. Continuous further development in the field of knife materials with parallel state-of-the-art production guarantees a high standard of quality.

DIENES is your OEM partner for high-volume slitting solutions with high process reliability.

Straight knives

DIENES long knives are the result of intensive research into optimum slitting processes for different types of material. Our products made of high-alloy steel, powder metallurgical steel (DPM), carbide and special materials are mainly used as stable solutions in the paper manufacturing and processing industry as well as in metal and steel processing.

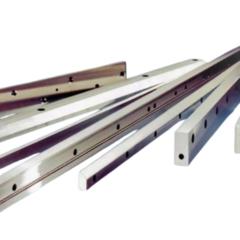

Guide rails

In addition to their hardness and professionally ground surface, DIENES guide pads impress with their µm accuracy. Our customers’ machines must reliably deliver top performance day after day. To ensure this, DIENES manufactures high-precision and stable guide gibs and guideways for mechanical engineering and special machine construction. These can also be used in a variety of ways: for example, as roller and sliding guides for use in machine tools and transfer lines.

Our straight knives

-

![Führungsleisten]() Shear cut

Shear cutGuide rails

Show more -

![DIENES Straight knives for cutting.]() Rotary cut, Shear cut

Rotary cut, Shear cutStraight knives for granulators and recycling

Show more -

![Pictured is a DIENES straight knife range.]() Shear cut

Shear cutCross cut knives and roll splitting knife

Show more -

![The picture shows cutting sticks from DIENES.]() Punched cut

Punched cutCutting sticks

Show more -

![Pictured are scrap chopper from DIENES.]() Rotary cut, Shear cut

Rotary cut, Shear cutShear blades and scrap chopper

Show more -

![Pictured is a range of paper cutting knives, tack cutter, three-knife trimmer and trimmer knife.]() Punched cut, Shear cut

Punched cut, Shear cutPaper cutting knives, tack cutter, three-knife trimmer and trimmer knife

Show more