Service and development

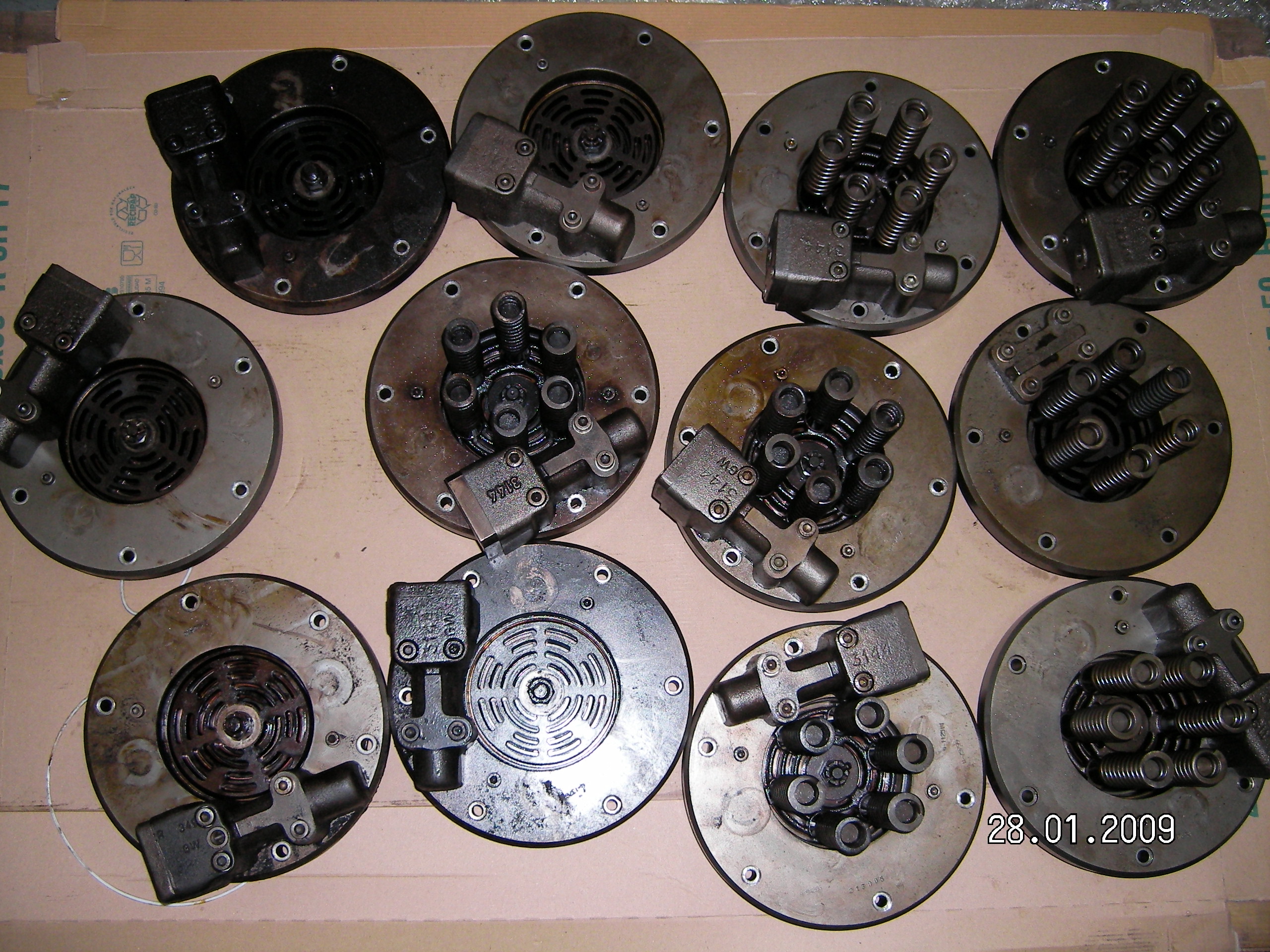

An all-round service for satisfied customers is part and parcel of DIENES. And not only for our industrial cutting tools, but of course also for our valves.

Our all-round service

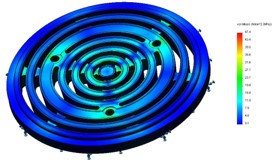

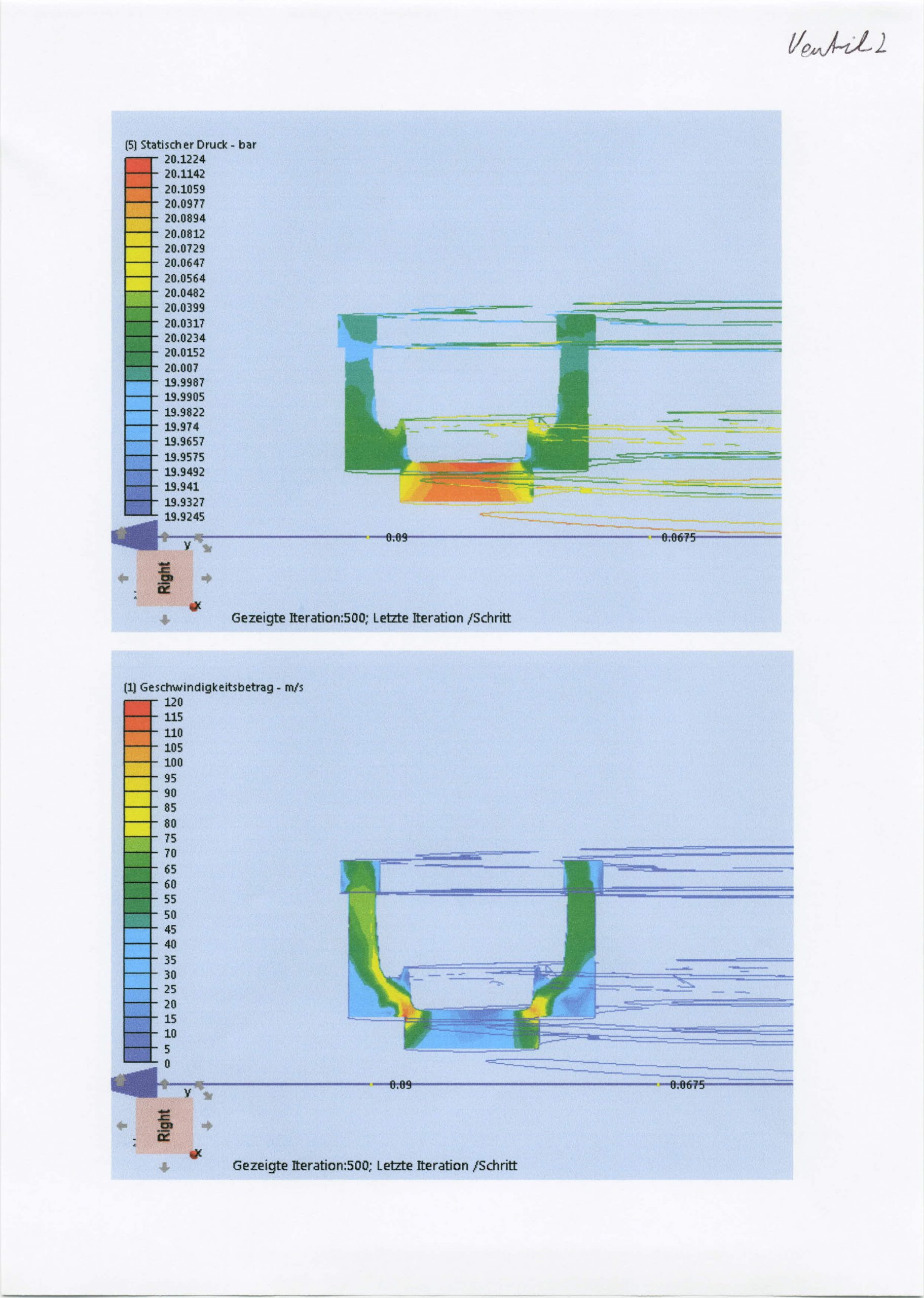

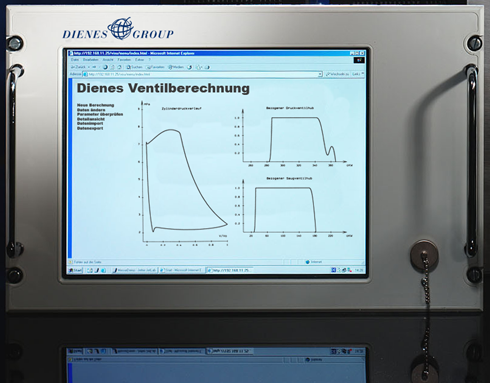

Various valve optimization tools are available to improve performance and cost-effectiveness. For example, strength and flow analyses or computer simulations can provide crucial insights to optimize your production process.

The following points are included in our service offered to OEMs:

- 3D CAD valve configuration

- Strength analysis

- Flow analysis

- Computer-Simulation

- Repair

These are used both for new developments and for compressor optimization during the repair of valve components.