Valves for high performance applications

For use in oxygen, CO2, CNG or PET compressors, valves for technical gases, valves for oil-free air, valves for industry as well as in refrigeration applications.

-

DS Valves

DIENES DS high-speed valves with frictionless guided plate parts are designed for installation in high-speed, dry-running compressors as well as for normal compressors for maximum performance and operational reliability. Small slot widths in the valve seats with maximum utilization of the valve diameters result in low plate strokes and thus short opening and closing times.

This valve series, which has proven itself over many years, is particularly suitable for demanding applications due to the friction-free valve plate guide.In addition, optimum utilization of the installation conditions and definition of as many piercing slots as possible result in low valve plate strokes and thus short opening and closing times.

Thin, low-mass valve and damper plates are guided by their own internal spring links. The completely frictionless design is ideally suited for use in intermittent and stepless regulators.

The length of the spring links and the thinness of the plates eliminate the need for the usual grinding of the link arms and reduce the risk of breakage in the bending zone.

Cylindrical coil springs are used for plate loading. The subdivision of the stroke reduces the bending load on the spring control arms. Effective mass damping is achieved by one or more damper plates in the upper third of the plate stroke.Special features:

- Small slot widths in the valve seats with maximum utilization of the valve diameters result in low plate strokes and thus short opening and closing times.

- Thin, low-mass valve and damper plates are guided by their own internal spring links.

- The completely frictionless design is ideally suited for use in intermittent and stepless control applications.

- Cylindrical coil springs are used for plate loading.

- The length of the spring links and the small plate thickness make the usual grinding-in unnecessary and reduce the risk of breakage in the bending zone.

- The subdivision of the stroke (3 stroke shims) reduces the bending work of the spring links.

- Effective mass damping is achieved by one or more damper plates in the upper third of the plate stroke.

- For capacity control of the compressor with lift-off gripper for valve plate control available

- Valve and performance optimization by computer simulation as a service for our customers.

-

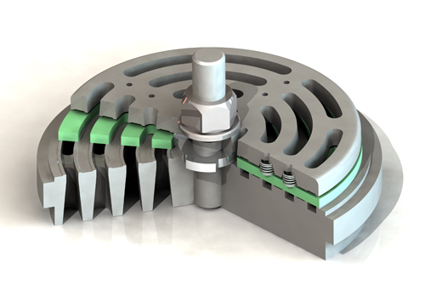

Quick open DA valves

The DIENES DA valves are frictionless guided plate valves which can be used in all types of reciprocating compressors, preferably in high performance compressors. The typical feature is the link arms arranged in the central plate area, which give the whole system an excellent stabilizing property, as the figure clearly shows.

The essential feature of DA valves is the arrangement of three fastening elements evenly distributed over the entire valve.

This innovative design creates an extremely rigid valve structure that allows unrestricted use of any installation position and inflow conditions in the room.Due to the centrally arranged link arms, the flow cross-section related to the valve area is increased (up to 30% depending on the size).

This significantly increases the achievable efficiency, while at the same time increasing the service life due to reduced valve plate strokes.The new lift-off system, which is of course also frictionless, blends harmoniously into the overall design.

Special features:

- Frictionless guided plate parts as a typical feature, link arms located in the central plate area

- Excellent stabilizing property due to long concentrically arranged link arms.

- Suitable for absolutely oil-free operation for capacity control of the compressor available with lift-off gripper for valve plate control

- Valve and performance optimization by computer simulation as a service for our customers

-

Quick open DK valves

The DIENES DK valves combine the advantages of concentric valves with the advantages of laser manufacturing, especially with regard to the highly stressed internal valve parts, and are also friction-free.

The core of each DK valve is the common one-piece laser valve plate for the suction and pressure areas. Its advantages are clear: freedom from friction in suction and pressure and increased service life.

As a special feature of this protected design, the number of moving plate parts in the valve is reduced.

This design uses only one valve plate (combined for suction and pressure).

Additional springs / spring plates are not required.DIENES DK valves are also simple in design, have low clearance, seal reliably between suction and discharge, and have only low moving masses – all basic requirements for high operational reliability at high compressor speeds.

Special features:

- No friction in suction and discharge sections

- Increased service life due to laser technology

- Reduced number of individual components

- Easy to maintain

DIENES DK valves

- Are also simple in design

- Have a small clearance

- Seal reliably between suction and pressure

- Have only low moving masses

- Valve and performance optimization by computer simulation as a service for our customers.

-

GS-K Valves

The DIENES GS-K valves are the further development of the proven GN series for preferred use in process gas compressors.

Here, the proven valve plate guidance of the standard steel valve plates has been combined with the use of plastic valve plates.

The plastic qualities used are precisely matched to the operating conditions.

This leads to improved service life under demanding operating conditions and critical gas compositions with optimum utilization of space.

For operating pressures above 50 – 70 bar, additional damping elements can be provided depending on the compressor speed and gas composition.

Operation is equally possible in oil-lubricated and dry-running compressors.

The use of lift-off devices for compressor regulation is also provided.Special features:

- Use of media-resistant high-performance plastics

- Low moving masses, thus quiet running and long service life

- Suitable for lubricated compressors as well as absolutely oil-free operation

- For capacity control of the compressor with lift-off gripper for valve plate control available

- Valve and performance optimization by computer simulation as a service for our customers

-

Concentric valves

Large gap cross-sections and thus low air velocities, small damage spaces and thus good filling ratio, best utilization of space, long service life of the plate parts, safety due to closed design, simple design of the cylinder head.

These advantages recommend the valves especially for installation in high-speed compressors with a small cylinder diameter in relation to the piston stroke.

Concentric DIENES Dicron valves are supplied both according to factory standards and in special designs with various material compositions. DIENES Dicron valves are also available with cooling fins on the outer circumference. These help to dissipate the heat of compression. In addition, they feature low-mass individual ring plates in the pressure section, which are loaded by impact- and noise-damping spring assemblies.

All in all, DIENES Dicron valves can be adapted to all installation conditions in a practical and favorable manner in terms of production technology. This applies equally to air-cooled, water-cooled, regulated and unregulated compressors. The manufacture of cylinders and cylinder heads is trouble-free.

Valve and performance optimization by computer simulation as a service for our customers.