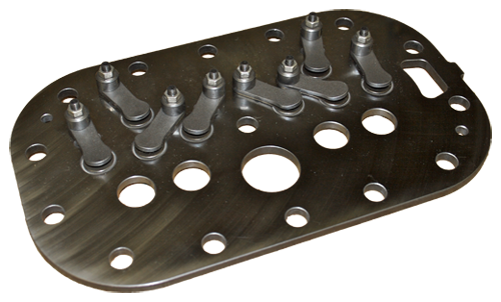

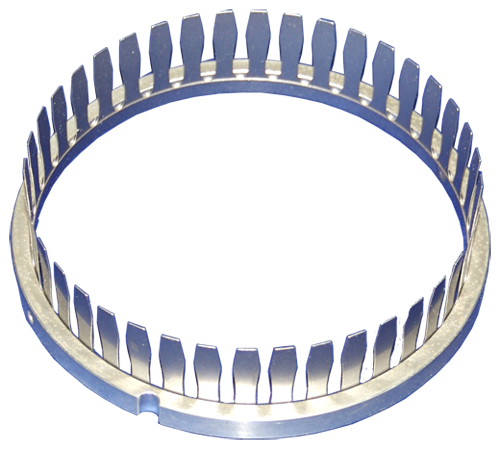

Low-damage valves for refrigeration systems, e.g. for industrial refrigeration or air-conditioning systems, concentric valves (with control in some cases). The external shape of the valves for DC compressors is adapted to the special installation conditions. Depending on the operating conditions, the valves are provided with individual rings or slotted plates. Multi-layer plate springs ensure effective impact damping, resulting not only in quieter air but also in increased operating reliability.

In the case of counterflow compressors, the suction valve seat is often incorporated in the cylinder liner to ensure function as well as mating. We recommend that the valves be purchased complete, i.e. including the liner. The quality of the cylinder bore complies with the respective regulations.

Special features:

- Designed for compressors with high compression ratios, such as chillers

- Optimum utilization of the installation space

- Low-loss flow guidance

- Guarantee favorable performance values and excellent efficiencies

- Valve and performance optimization by computer simulation as a service for our customers