Products for rotary compressors (oil-free compressing)

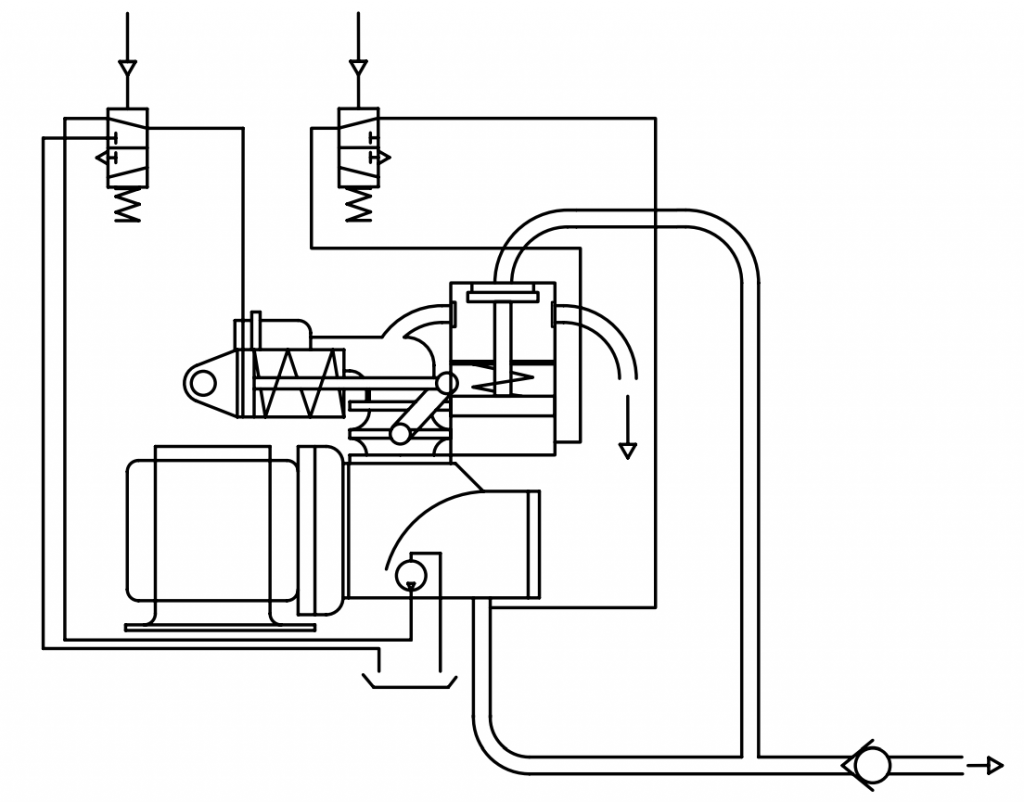

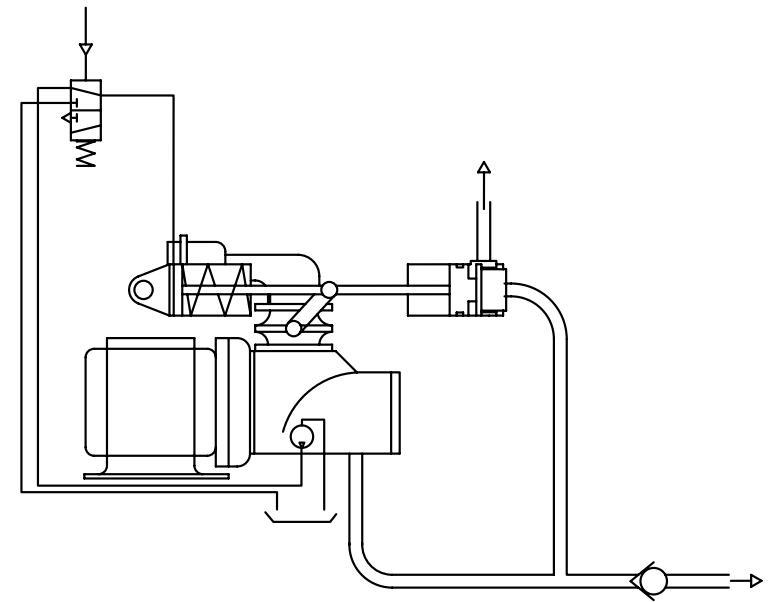

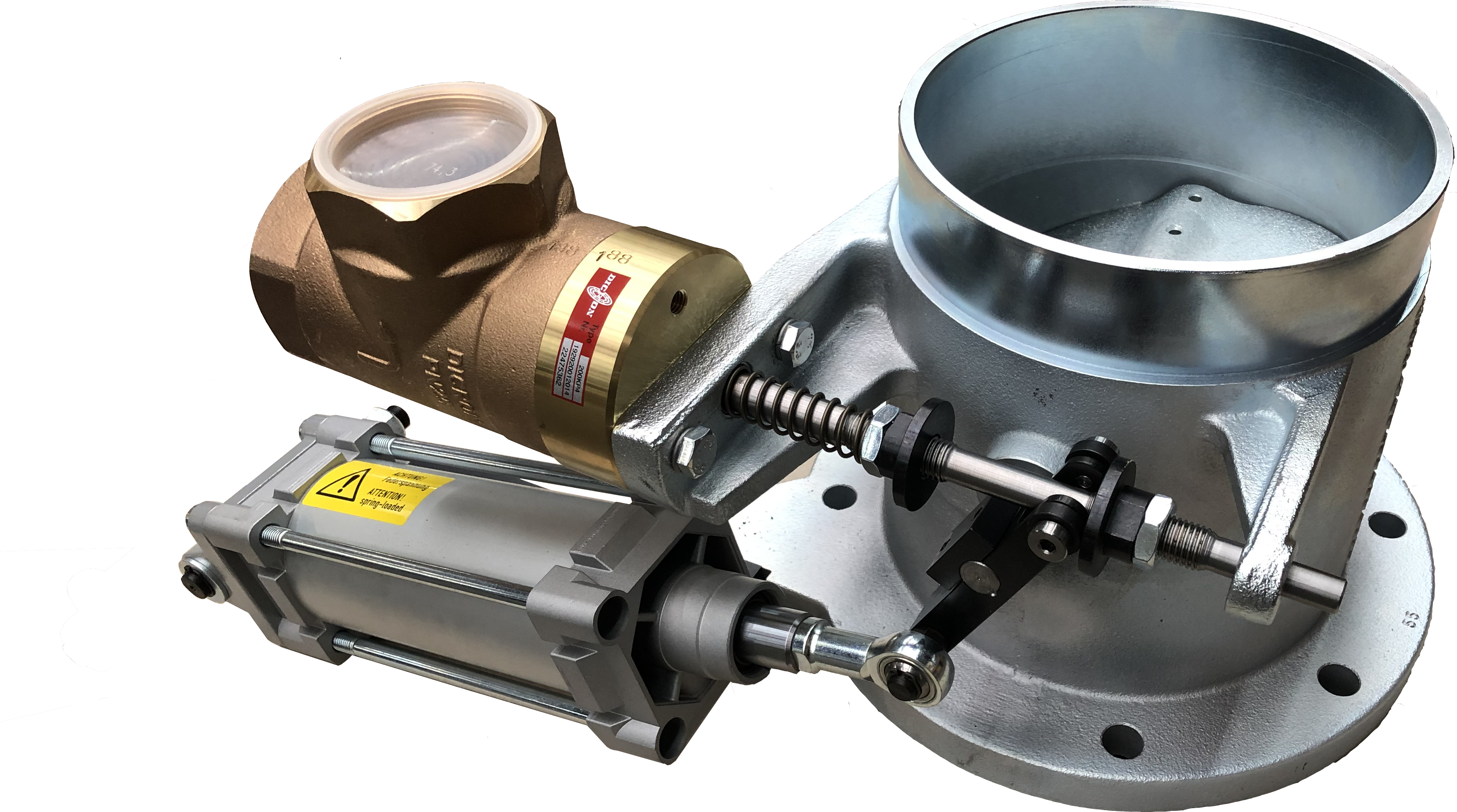

Dry-compressing screw compressor stages for the generation of completely oil-free compressed air require a different control method from oil-flooded or water-injected screw compressor stages. Here, safety mechanisms must be installed in addition to the load/no-load control. During no-load operation, sufficient bypass air volume must be guaranteed for internal stage cooling, and the compressed air must be relieved of atmospheric pressure to prevent overheating of the compressor stage due to an impermissibly high internal compression ratio.