Our quality promise

DIENES makes the difference

It is not easy to recognize the quality of a knife at first glance. Often, one knife is like another – dimensions and appearance do not suggest any differences. But it is the inner values, i.e. the material used, on the one hand, and the factors of service life and manufacturing reliability in your ongoing production on the other that matter. In practical terms, this means that “real” knife quality must have a long service life with consistent cutting quality and an extremely low risk of breakage and splintering. This is the only way to guarantee a safe and uninterrupted production process.

This is exactly what our in-house development engineers and our production staff have been focusing on for over 100 years. Depending on the application and cutting geometry, the stress on the cutting edges is very complex. In varying degrees, this has a decisive influence on the service life of the blades. At the point of contact, wear, bending stress and flash temperatures occur due to the friction between the upper and lower knives. Knife materials with adapted hardness and high toughness show the inner values of our knives, which have comparatively high knife service lives. In addition, we have continuous quality assurance processes throughout the entire knife production, which ensure the exceptional quality of our knives.

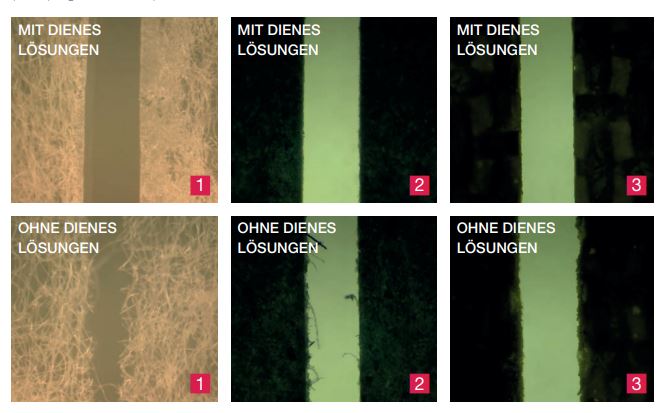

Here we see clean, precise cut edges produced by DIENES solutions in the top row of images in direct comparison to conventional, inferior cut edges in the bottom row of images. The highlighted images show the cut edge of nonwoven (image 1), paper (image 2) and prepreg (pre-impregnated fibers) (image 3).

Highest material quality

We work only with certified and long-standing partner companies. Our partners only use steel of known origin and guarantee us a specific melt analysis. Only in this way, we can ensure that supplied steels always offer the same quality also after further processing. We do not use bulk steels from the trade with unknown origins. This is because in the case of steels from unclear origins, a slight deviation in steel composition can lead to deviations in the hardening and tempering process. This in turn would result in quality variations in the knives. Depending on the application (especially for roller shears), special steels with defined melt analysis are used to meet customer requirements. These required steel grades are constantly tested. In this way, we can guarantee the best homogeneity and batch purity of the material of our products as well as the highest material quality throughout.

Holistic manufacturing know-how

To achieve the desired knife properties, the steels are carefully machined during the manufacturing process. The subsequent heat treatment is precisely tailored to the workpiece used and is constantly monitored. The time and temperature sequences are precisely coordinated to achieve the desired toughness of the knife.

Constant further development

Since then, absolute precision and clean cutting edges have been the focus of our developments. In this way, we have repeatedly set new standards in industrial cutting and have become the cross-industry specialist for a wide variety of cutting materials. We will continue to do so in the future thanks to our own development department with more than 20 highly trained engineers for our demanding customers all over the world. In particular, four outstanding, patented developments from our company contribute to a flawless cut:,

Constant quality control

As a DIN EN ISO 9001 certified company, we rely on systematic quality controls that are firmly anchored in our processes in order to achieve the quality we demand, both consistently and in the long term. Not only our raw material is carefully checked but also production steps up and finally the finished knife. This includes, for example the optimal design and knife geometry. Among other things, we also rely on the proven Finite Element Method (FEM). In this way, we continuously develop our product quality as well as the products in their function.

Product-specific logistics

Even the smallest damage can impair knife quality and thus service life and production reliability. Therefore, we have established intelligent solutions especially for the storage as well as the transport of high-quality industrial knives.