Crush cut

In the crush cut, a crush knife pierces the material web. A hardened shaft or hardened rings are used as the counter knife. The crush cut knife located in the holder works under pressure against the glass-hard surface of a cutting roll and cuts there, regardless of the setting of the lower knives. The resulting cut edges are basically worse than in shear cutting due to the cutting process by “squeezing”. An improvement can be realized by different knives and radius geometries.

Basically, the smaller the included angle and radius, the better the cut quality with the disadvantage of shorter blade life. “One size fits all” in terms of cutting materials and knife geometries unfortunately does not exist for crush cutting either. On the one hand, customer requirements are different, and on the other hand, the cutting materials differ in terms of thickness and consistency.

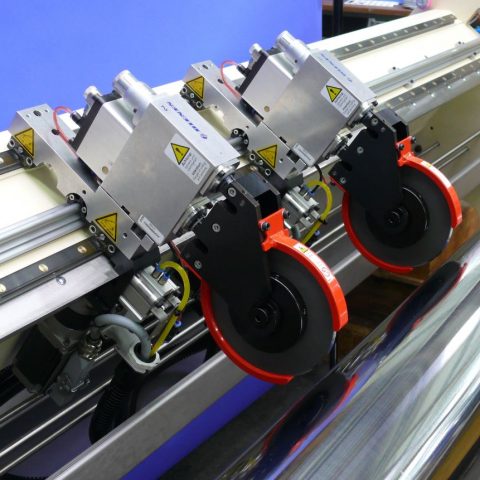

There are special knife holders for crush cutting. They are used for cutting paper, rubber, textiles and even adhesive materials, with a wide variety of holder designs being used depending on the required cutting width, cutting force and speed.

DIENES Know-How

Our all-rounders are the DIENES crush cut holders type PQDS and PQAS. These have proven themselves in use with a wide variety of materials at a cutting speed of up to 300 m/min. The air pressure should be adjusted to the respective material to be cut. Excessive increases in cutting pressure lead to cylindrical knife edges and a drastic reduction in tool life. On the other hand, too low cutting pressure should also be avoided. It is possible that due to a too low cutting pressure and the production-related concentricity deviations of the pinch knives, as well as the counter shaft, there is no constant contact. This results in micro-vibrations of the pinch knife, which increase drastically with increasing speed. DIENES crush cutters and counter shafts are therefore manufactured with minimum concentricity deviations. The use of higher alloyed pinch knives will only result in a better service life if all relevant adjustment parameters have been set correctly.

Matching DIENES products